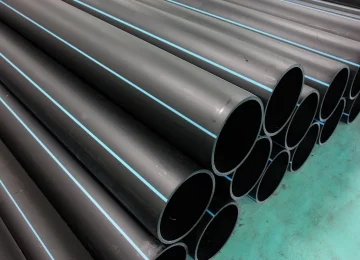

Reliable HDPE Pipe Solutions for Your Needs

When it comes to modern piping solutions, High-Density Polyethylene (HDPE) pipes have become a game-changer. Whether you’re dealing with water supply, gas distribution, or sewage systems, choosing the right piping material is crucial for long-term performance and reliability. But with so many options available, why do experts recommend HDPE pipes? This comprehensive guide will delve into everything you need to know about HDPE pipes—highlighting their unmatched durability, flexibility, and cost-effectiveness. By the end of this article, you’ll understand why HDPE pipes are increasingly the go-to solution for diverse piping needs.

What are HDPE Pipes?

HDPE pipes are made from high-density polyethylene, a thermoplastic polymer known for its high strength-to-density ratio. These pipes are recognized for their superior durability, chemical resistance, and flexibility, making them ideal for a variety of industrial and residential applications. But what sets HDPE pipes apart from other types of piping?

Key Benefits of HDPE Pipes

1. Durability and Longevity

HDPE pipes are renowned for their longevity. Unlike traditional metal or PVC pipes, HDPE pipes are highly resistant to corrosion, cracking, and leaks. This makes them an excellent choice for systems that need to last for decades without frequent maintenance.

2. Flexibility

One of the standout features of HDPE pipes is their flexibility. This makes them suitable for installation in areas with difficult terrains or where seismic activity is common. The flexibility also reduces the need for fittings, which can lower installation costs and time.

3. Chemical Resistance

HDPE pipes have superior chemical resistance, allowing them to handle a wide range of fluids without deteriorating. This makes them ideal for use in chemical plants, wastewater treatment facilities, and agricultural applications.

4. Cost-Effectiveness

While the initial cost of HDPE pipes may be higher than some alternatives, their long-term benefits—including lower maintenance costs, fewer repairs, and a longer lifespan—make them a cost-effective solution over time.

5. Environmental Benefits

HDPE pipes are not only durable but also environmentally friendly. They require less energy to manufacture and transport, and they are fully recyclable. This makes them an excellent choice for sustainable construction projects.

Common Applications of HDPE Pipes

1. Water Supply Systems

HDPE pipes are widely used in potable water supply systems due to their durability, flexibility, and non-toxic nature. They are also resistant to biofouling, which ensures clean water delivery over long periods.

2. Gas Distribution

The flexibility and strength of HDPE pipes make them ideal for gas distribution networks. They can withstand high pressures and are resistant to leaks, ensuring safe and efficient gas delivery.

3. Sewage and Drainage

HDPE pipes are commonly used in sewage and drainage systems because of their resistance to corrosion and chemicals. Their smooth interior surface also minimizes the risk of blockages, ensuring efficient wastewater flow.

4. Agricultural Irrigation

In agriculture, HDPE pipes are used for irrigation systems due to their high strength and flexibility. They can withstand harsh environmental conditions and deliver water efficiently to crops, ensuring better yield.

5. Industrial Applications

HDPE pipes are also used in various industrial applications, including slurry pipelines, chemical processing, and oil and gas transportation, thanks to their chemical resistance and durability.

Installation and Maintenance Tips

Proper installation is crucial to maximizing the lifespan and performance of HDPE pipes. Here are some key tips:

1. Trench Preparation

Ensure the trench is deep and wide enough to accommodate the pipe, with a stable base to prevent shifting or sagging.

2. Jointing Techniques

Use appropriate jointing methods like butt fusion, electrofusion, or mechanical fittings to ensure strong, leak-free connections.

3. Pressure Testing

Conduct pressure tests before covering the pipes to detect any potential leaks and ensure the system’s integrity.

4. Regular Inspections

While HDPE pipes require minimal maintenance, regular inspections can help identify and address issues before they become major problems.

Conclusion

HDPE pipes offer a reliable, durable, and cost-effective solution for a wide range of piping needs. From water supply to industrial applications, their benefits are clear—making them the preferred choice for modern infrastructure projects. By understanding the advantages and best practices for installation and maintenance, you can ensure that your HDPE piping system delivers optimal performance for decades.